Relationship Between Hard Chrome Plating, Mirror Polishing, and Mold Surface Quality

Relationship Between Hard Chrome Plating, Mirror Polishing, and Mold Surface Quality

Importance of Hard Chrome Plating and Mirror Polishing

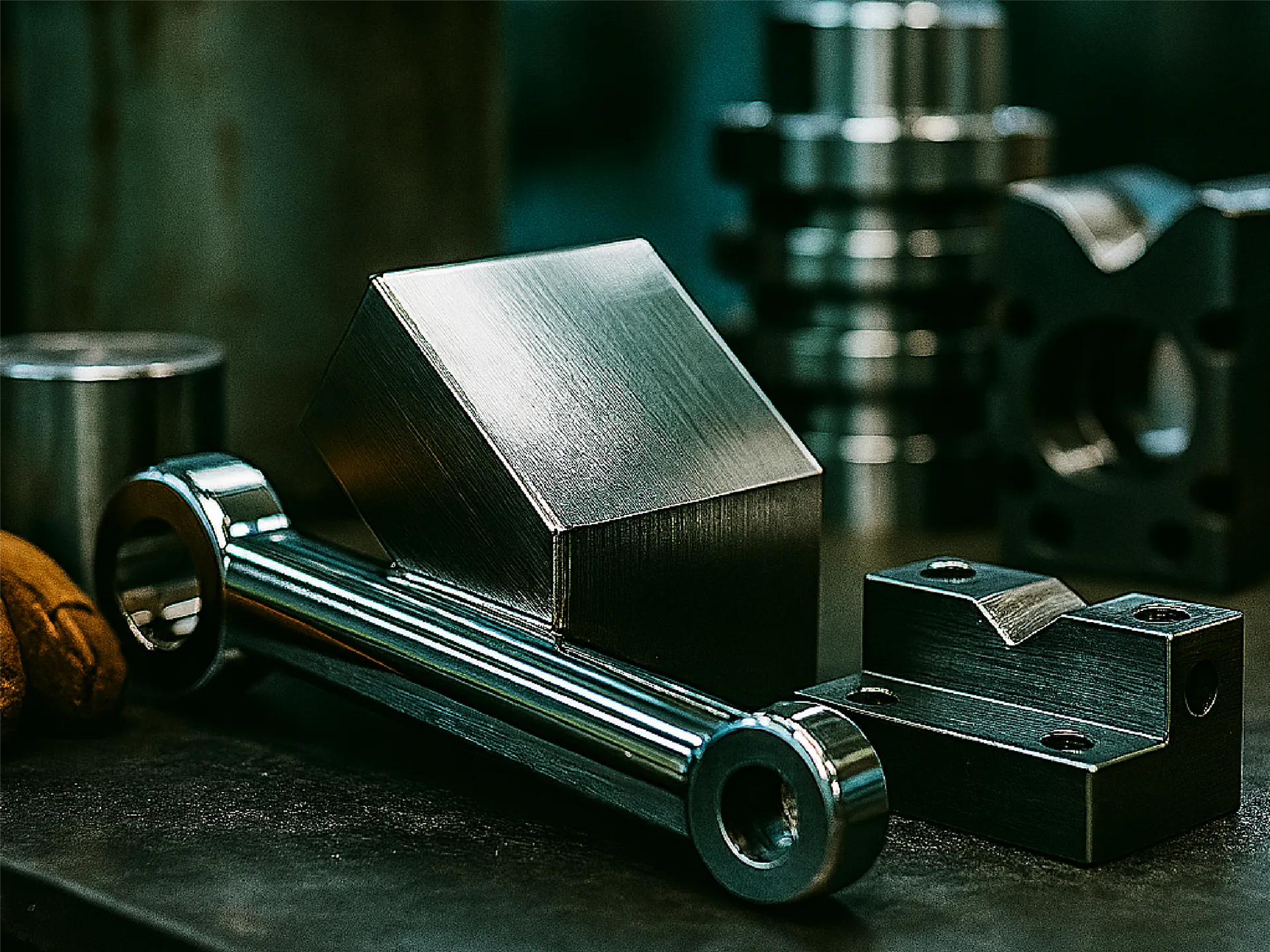

Hard chrome plating provides superior durability and brilliance to mold surfaces. When combined with mirror polishing, it minimizes surface roughness and creates a perfectly reflective surface. This combination not only improves the visual appeal of the product but also enhances its overall quality and performance in production processes.

- Minimizes surface roughness to the lowest possible level

- Provides long-lasting brightness and protection through the hard chrome layer

Effect of Hard Chrome Plating on Mold Surface Quality

Hard chrome plating fills micro-imperfections on the mold surface, forming a uniform and dense structure. This makes mirror polishing easier and more effective. Hard chrome–plated molds ensure smoother material flow, reduce friction during molding, and improve dimensional accuracy and surface quality of the final product.

- Optimizes material flow and reduces deformation during molding

- Maintains production tolerances and minimizes defect rates

Role of Hard Chrome in Productivity and Durability

The high hardness and low friction properties of hard chrome plating significantly reduce wear on mold surfaces. As a result, molds last longer, require less maintenance, and operate more efficiently. Mirror-polished hard chrome surfaces also enhance energy efficiency and process stability during production.

- Extends mold life and increases durability

- Reduces maintenance and re-polishing costs

- Improves production efficiency and shortens cycle time

Aesthetic and Market Advantages

When hard chrome plating is combined with mirror polishing, it delivers not only technical benefits but also strong aesthetic value. The reflective, smooth, and bright surfaces enhance the perceived quality of the product, strengthen brand reputation, and provide a competitive advantage in the market.

- Enhances product aesthetics and visual perception

- Improves brand value and competitive advantage

- Creates a premium, high-gloss surface finish