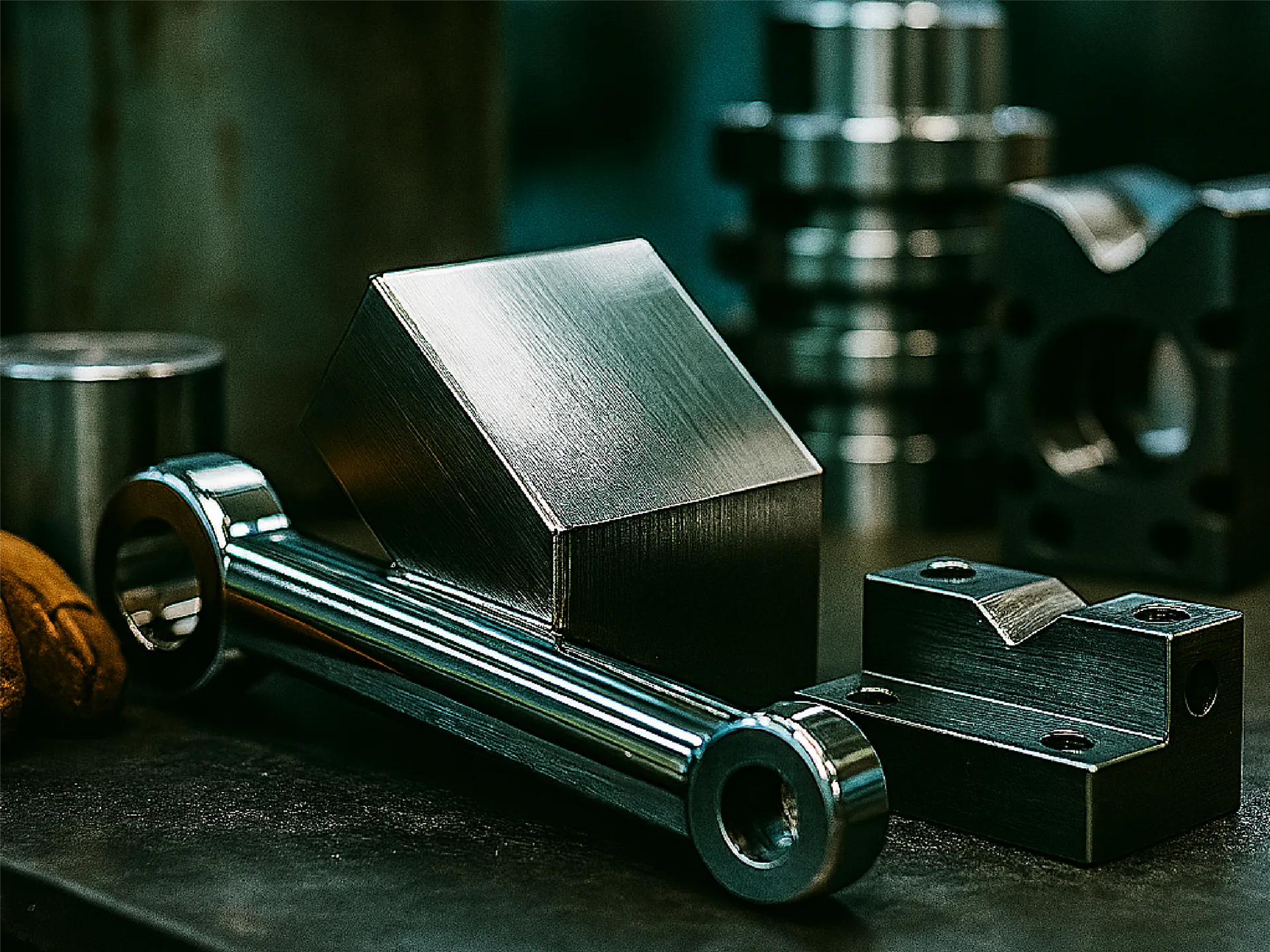

Importance of Choosing the Right Hard Chrome Plating in Mold Polishing

Importance of Choosing the Right Hard Chrome Plating in Mold Polishing

Why Is the Right Hard Chrome Selection Important?

The quality of the hard chrome plating used in the mold polishing process directly affects both the surface quality of the product and the lifespan of the mold. An incorrect plating type can cause micro-scratches, deformations during polishing, and visible defects on the product surface. Therefore, choosing the appropriate hard chrome plating according to production goals, mold material, and operating conditions is essential.

- Directly affects the surface quality after polishing

- Increases mold durability and service life

Advantages of Different Hard Chrome Coating Properties

Hard chrome coatings offer varying levels of performance and durability depending on the mold application. High hardness, low friction coefficient, and excellent corrosion resistance provide significant advantages in production processes. Especially for molds operating under high temperature or pressure, choosing the right hard chrome coating is critical for maximum efficiency.

- Optimizes corrosion resistance, hardness, and wear resistance

- Improves production efficiency and product performance

Effect on the Polishing Process

Selecting the proper hard chrome plating facilitates the polishing process and helps achieve the desired surface gloss in less time. High-quality hard chrome coatings create a uniform surface, resulting in smoother and more aesthetic finishes.

- Reduces polishing time

- Provides more uniform and high-quality surfaces

Importance in Terms of Cost and Efficiency

Incorrect coating selection can cause early wear of the mold and increase maintenance frequency, leading to higher production costs. Proper hard chrome plating extends mold life, reduces maintenance and re-coating expenses, and provides long-term economic benefits.

- Reduces maintenance and re-coating costs

- Enhances long-term production efficiency and quality stability