Extending the Lifespan of Metal Parts with Hard Chrome Plating Technologies

Extending the Lifespan of Metal Parts with Hard Chrome Plating Technologies

Hard Chrome Plating Technologies

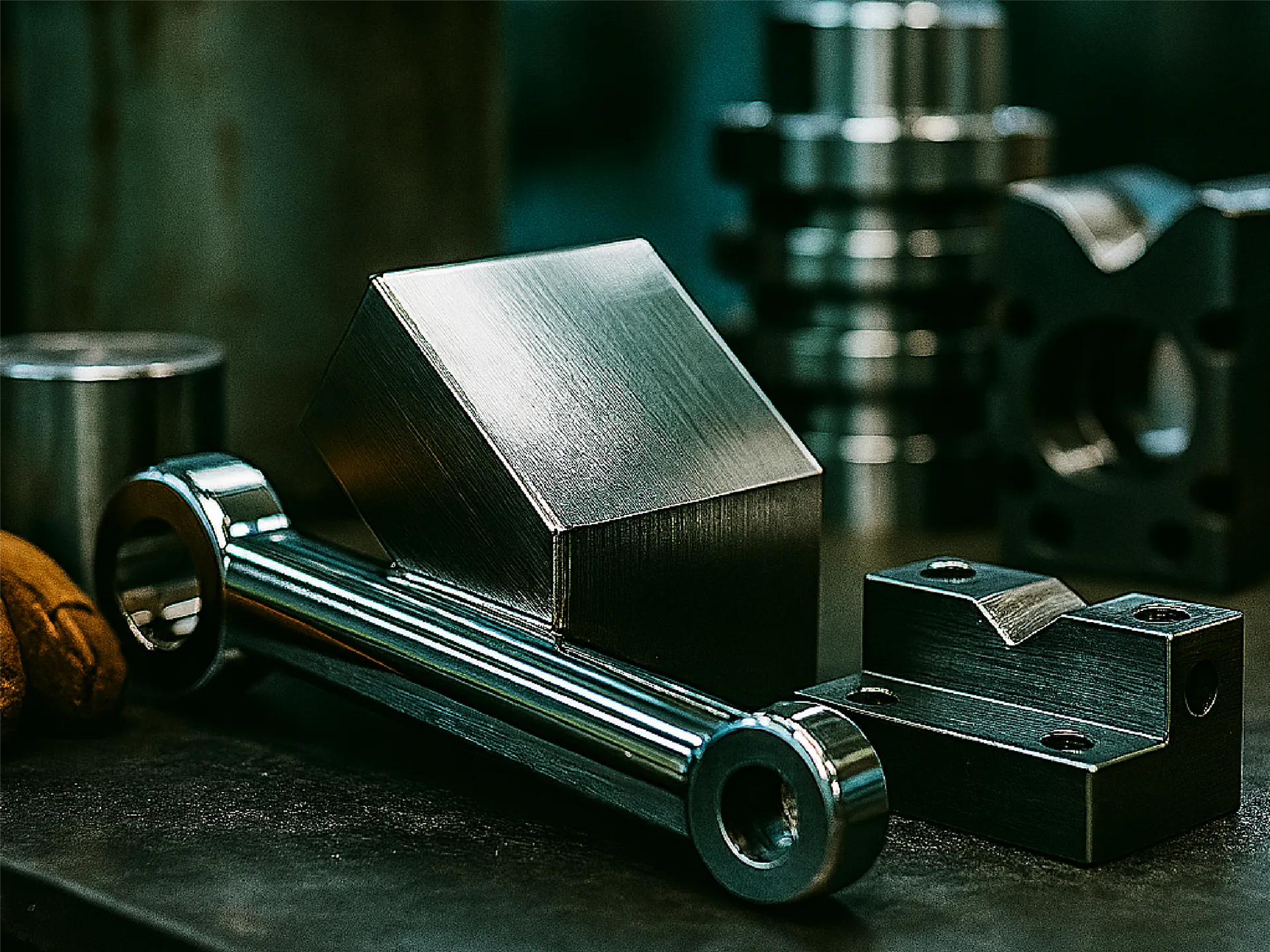

Hard chrome plating is one of the most effective surface treatment technologies for metal parts. This process enhances both the aesthetic appearance and the durability of components, providing high resistance against wear, corrosion, and chemical effects. Hard chrome plating, especially for steel parts, ensures long-lasting and high-performance surfaces.

- Provides superior resistance to corrosion and wear

- Improves surface quality and enhances brightness

The Role of Polishing and Mirror Finishing in Hard Chrome Plating

Pre-polishing and mirror finishing before hard chrome plating minimize surface roughness and ensure a more uniform and durable coating. The polished surface coated with hard chrome becomes smoother, shinier, and highly resistant to wear.

- Achieves maximum smoothness and gloss on the coated surface

- Reduces friction and extends mechanical lifespan of parts

Surface Hardening with Hard Chrome

Hard chrome plating naturally hardens the metal surface. This provides high surface hardness and strong protection against wear and deformation. Compared to traditional heat treatment or nitriding, hard chrome offers a smoother surface and reduces maintenance requirements.

- Provides high surface hardness and wear resistance

- Protects parts against deformation and external impacts

Electrochemical Hard Chrome Applications

Electrochemical hard chrome plating is one of the most reliable coating methods for metal surfaces. This technique forms a dense and uniform chrome layer, providing long-term corrosion protection. It maximizes durability in marine, automotive, tooling, and industrial applications.

- Delivers long-lasting and effective corrosion protection

- Significantly reduces maintenance and repair costs