Hard Chrome Plating Processes and Advantages

Hard Chrome Plating Processes and Advantages

What Is Hard Chrome Plating?

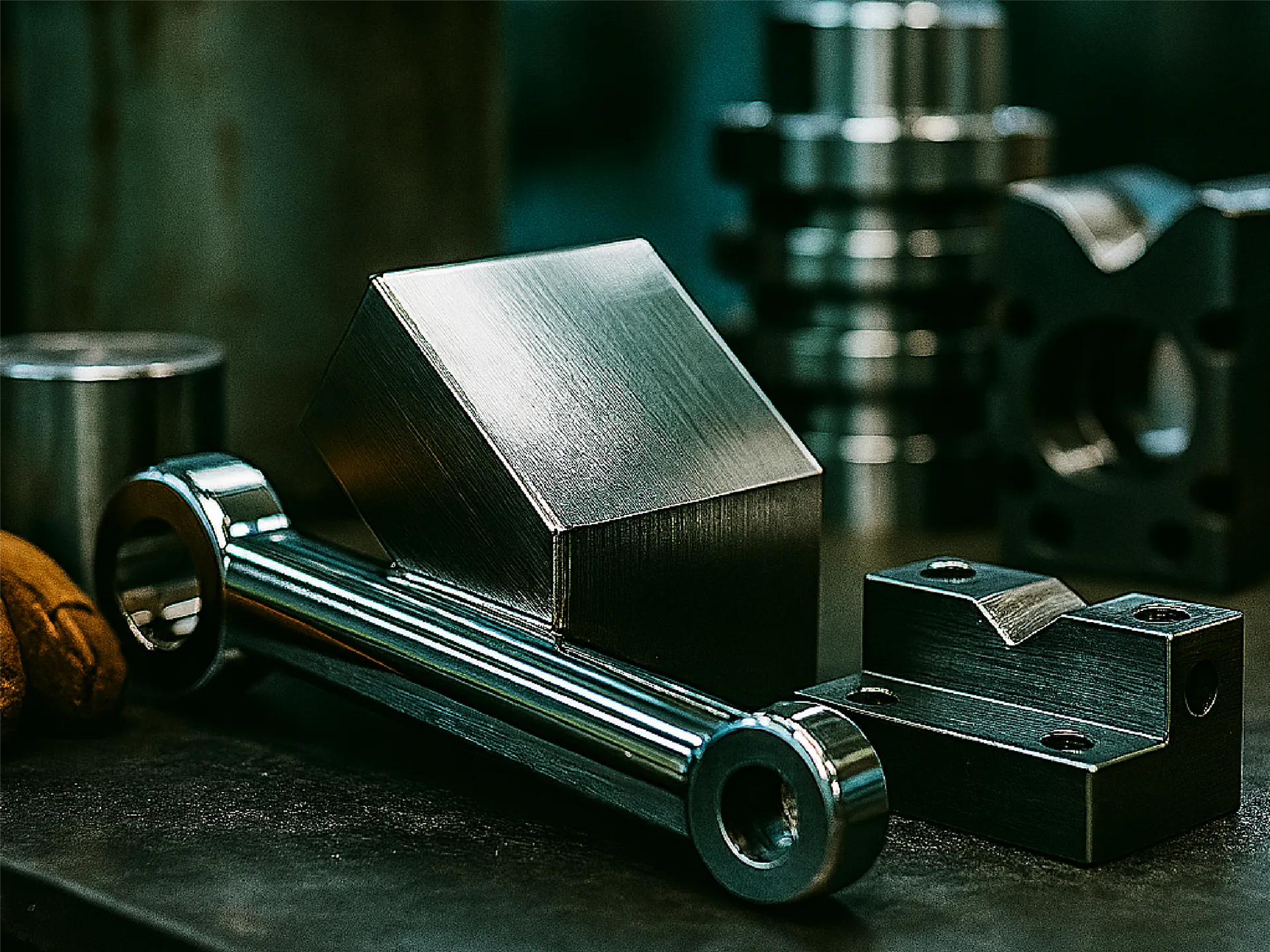

Hard chrome plating is an electrochemical process applied to metal surfaces to enhance durability, reduce wear, and provide long-term protection. This process gives metal components high surface hardness, superior wear resistance, and excellent corrosion protection. Widely used in the automotive, tooling, machinery, and aerospace industries, hard chrome plating delivers both functional performance and aesthetic brilliance.

- Significantly increases the mechanical strength of the surface

- Provides a bright and aesthetic metallic finish

Hard Chrome Plating Processes

The hard chrome plating process involves precise surface preparation and electrochemical coating stages. Typically, the process consists of four main steps: surface cleaning, pre-treatment, hard chrome deposition, and final finishing. Each step ensures optimal adhesion of the coating and uniform hardness distribution across the surface.

- Surface cleaning: Complete removal of oils, oxides, and contaminants

- Pre-treatment: Chemical preparation to enhance coating adhesion

- Hard chrome plating: Electrochemical deposition of the chromium layer

- Finishing: Polishing and dimensional correction for surface precision

Through this multi-step process, hard chrome plating produces a dense, smooth, and long-lasting surface layer.

Advantages of Hard Chrome Plating

The key advantage of hard chrome plating lies in its ability to maximize resistance against wear and corrosion. It also reduces friction, minimizing energy loss in mechanical systems. As a result, components last longer, require less maintenance, and maintain superior performance. The bright and uniform finish enhances the overall appearance of the product.

- Provides excellent wear and corrosion resistance

- Extends the lifespan of molds and machine components

- Reduces maintenance costs and improves productivity

- Creates a smooth, bright, and hard surface layer

Applications of Hard Chrome Plating

Hard chrome plating is widely used in industries where surface durability and precision are critical. Common applications include automotive parts, injection molds, pistons, hydraulic cylinders, press tools, and precision machinery components. Unlike decorative chrome, hard chrome plating serves a fully functional and industrial purpose.

- Used in mold, automotive, and machinery industries

- Ideal for high-performance and long-life components

- Ensures maximum protection in industrial and technical applications