- Home

- /

- Our Services

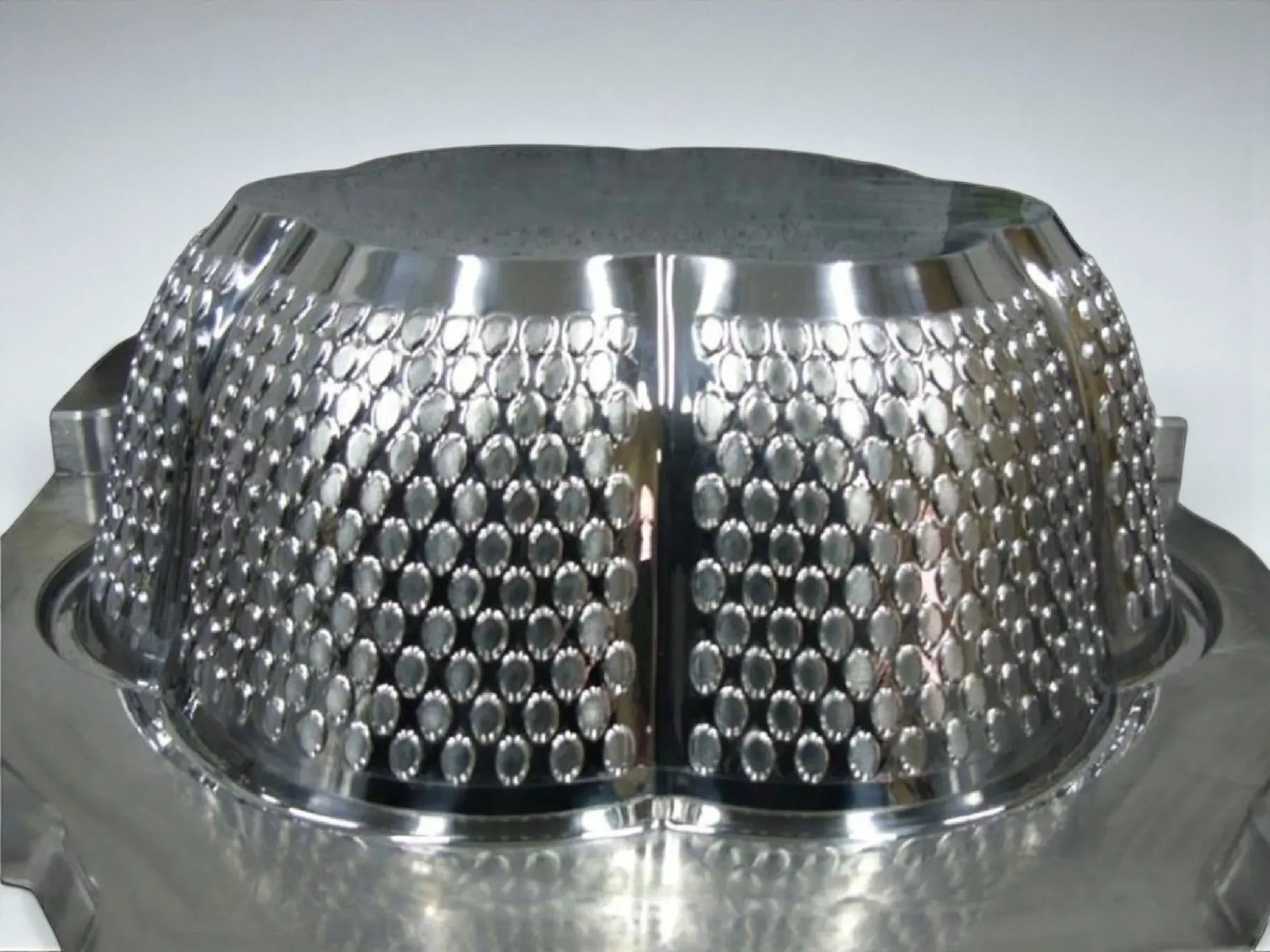

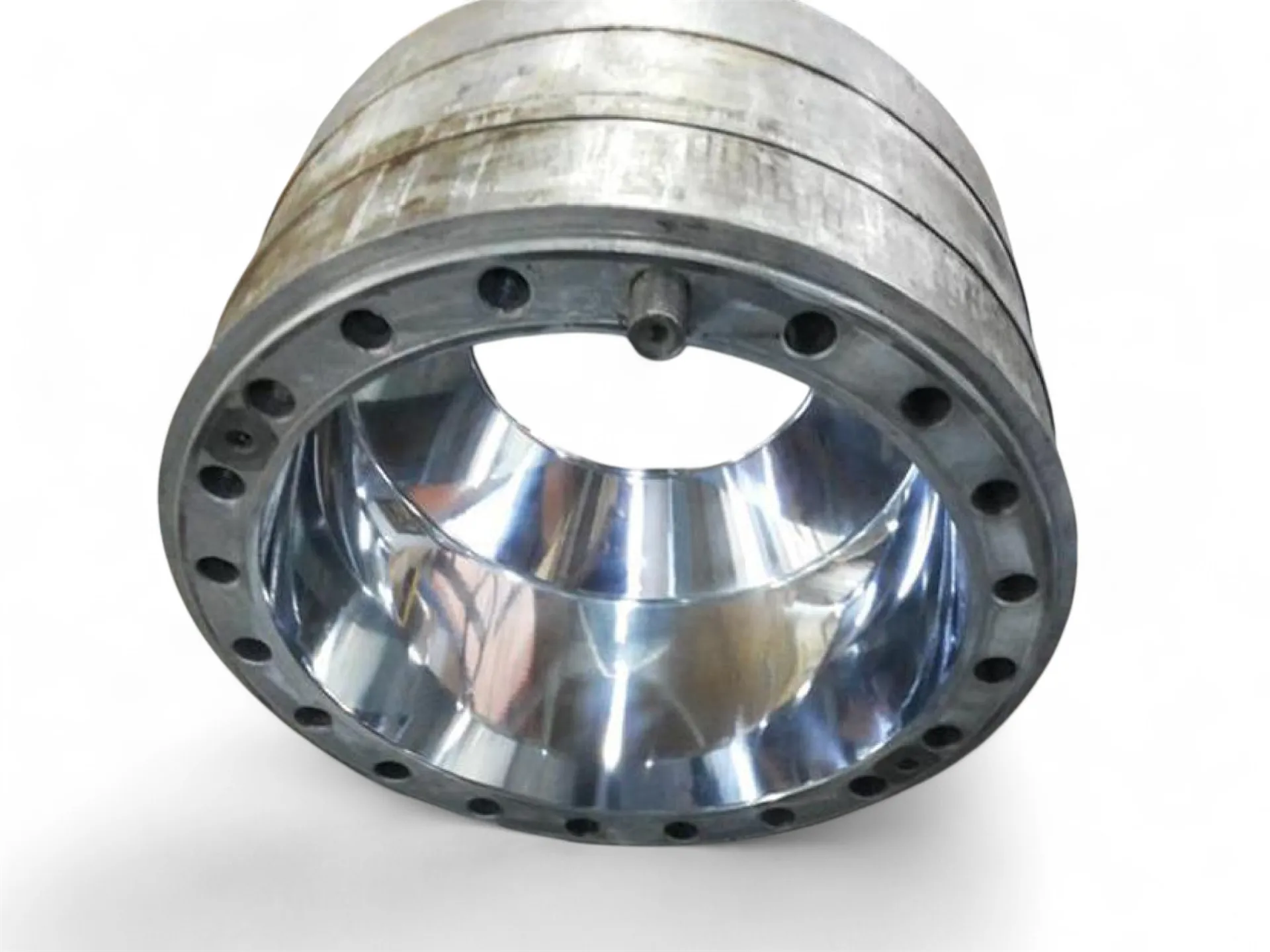

Precision Mold Polishing

Precision Mold Polishing

Precision mold polishing is a professional mold finishing process applied to injection molds made of materials such as plastic, melamine, bakelite, and rubber. It aims to smooth and clean the mold surface, enhancing the surface quality of the molded product. Mold polishing is a process that requires specific techniques, manual skill, attention, and patience.

Since mold polishing is the final stage of mold manufacturing, any mistakes (such as corner chipping or incorrect draft angles) are difficult to correct.

Mold polishing is primarily applied to parts that demand high aesthetics and visual quality, so the molds for these parts must be made more accurately. Although polishing is applied only to the working surface, achieving a high-quality surface depends on the steel used for the mold. The first condition for obtaining a very clean and bright surface is the proper selection of steel. For molds requiring high gloss, steel with a high chromium content should be used, or heat treatment and chromium plating should be applied.