Hard Chrome Plating Applications in the Packaging and Plastics Industry

Hard Chrome Plating Applications in the Packaging and Plastics Industry

Importance of Hard Chrome Plating

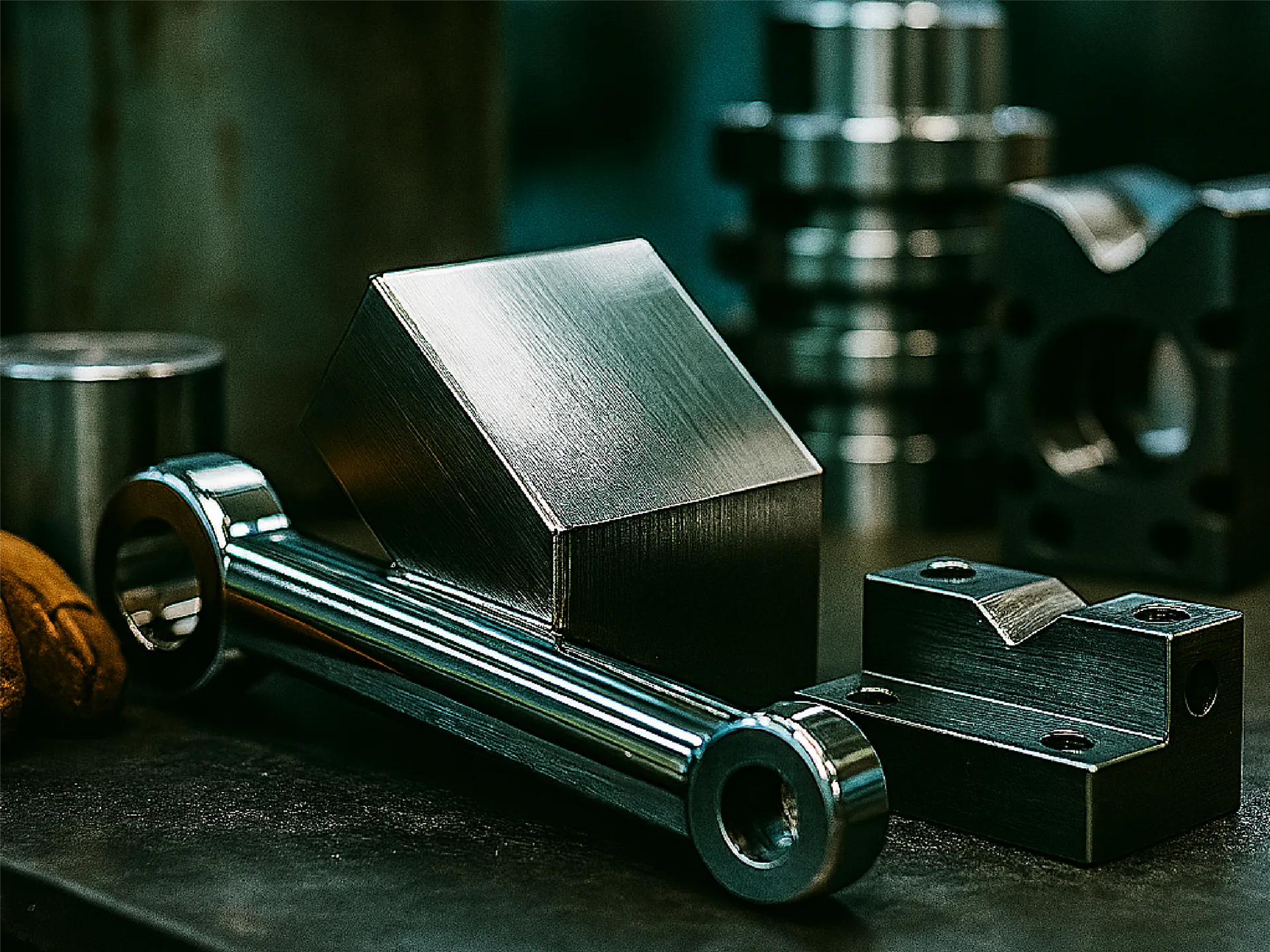

In the packaging and plastics industry, hard chrome plating plays a crucial role in enhancing mold durability and achieving superior surface quality. By applying hard chrome plating to mold surfaces, scratches, wear, and deformation are minimized, ensuring long-lasting, high-precision, and aesthetically refined products.

- Improves mold durability and extends service life

- Provides smooth and visually appealing surfaces

Applications of Hard Chrome Plating in the Plastics and Packaging Industry

Hard chrome plating is widely used in blow molds, injection molds, packaging container molds, and film extrusion molds. The coating improves surface smoothness and durability, enhances material flow during production, and ensures uniform gloss and precision in the final products.

- Used in bottle molds, containers, films, and injection molds

- Ensures smooth surfaces and high surface brightness

Advantages of Hard Chrome Plating

Hard chrome plating protects mold surfaces against wear, corrosion, and chemical effects. This reduces maintenance frequency, increases production continuity, and lowers operational costs. In addition, it enhances the aesthetic quality of finished products, providing a strong competitive advantage in the market.

- Provides superior resistance against wear and corrosion

- Reduces maintenance and reconditioning costs

- Enhances product aesthetics and market competitiveness

Contribution to Efficiency and Quality

Hard chrome–plated molds reduce friction during the molding process, allowing for smoother material flow and more stable production. This not only increases production speed but also ensures consistent product quality. Furthermore, hard chrome plating supports energy-efficient manufacturing, offering both economic and environmental benefits.

- Increases production efficiency and shortens cycle times

- Maximizes surface quality and gloss

- Provides long-term economic and environmental benefits